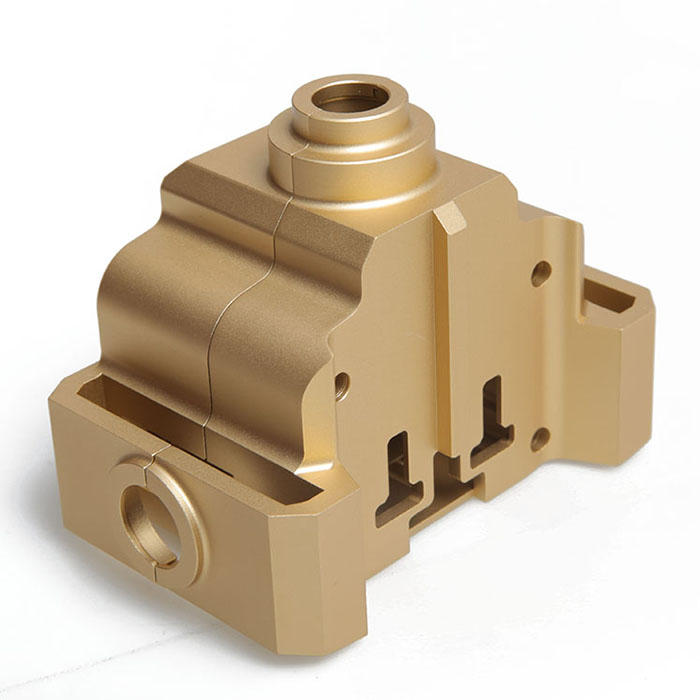

Wholesale China Cnc Milling Parts Factory Quotes – Factory black oxidation aluminum milling precision parts – Senze

Wholesale China Cnc Milling Parts Factory Quotes – Factory black oxidation aluminum milling precision parts – Senze Detail:

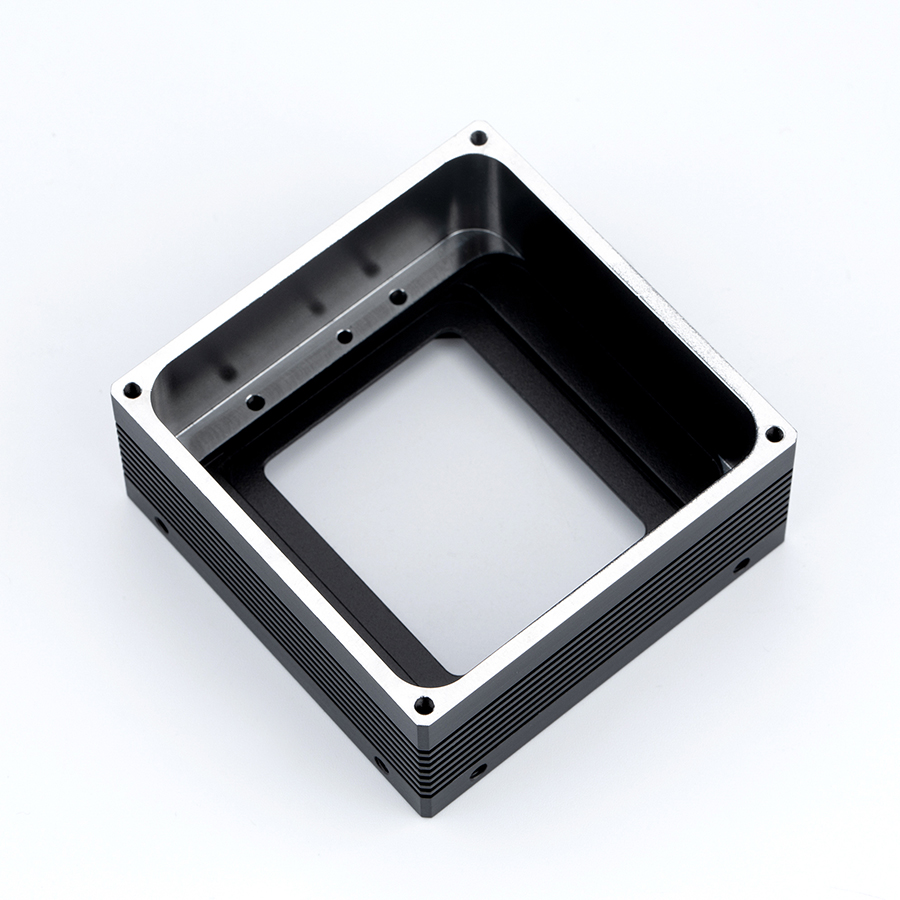

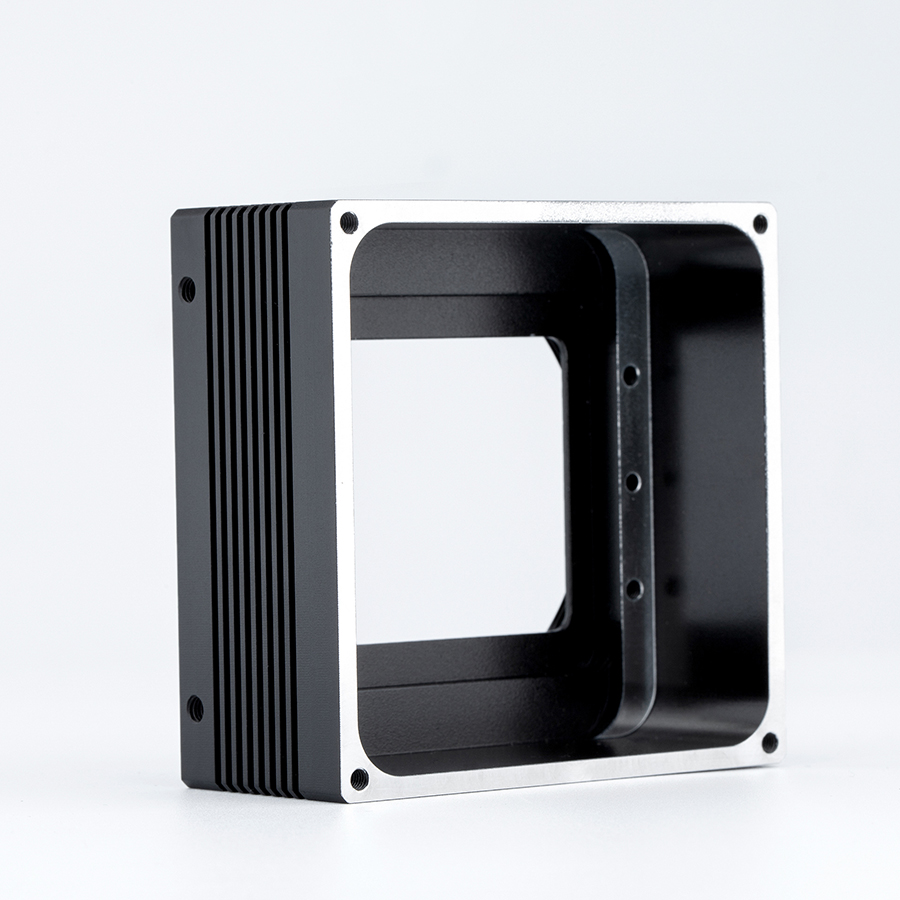

Milling machining

1. Machining square, rectangle, round+rectangle.

2. Used for processing planes, steps, grooves, gear teeth, threads, spline shafts, forming surfaces and cutting off workpieces, also process more complex profiles etc…

3. High efficiency, high precision.

4. It is widely used in machinery manufacturing and repair departments.

What Kinds Of Material Can Be CNC Milled?

While potentially any solid, stable material can be milled, we have a standard selection of raw material including hard plastics and aluminum, various steels, titanium, magnesium, brass, copper and other alloys.

Note that some hardened steels may be too hard to CNC machine, or else would require specialty cutting tools and longer processing times. Soft elastomers or plastics may also be impossible to mill since they cannot be held in a fixed position or would change in shape under the pressure of the cutting tool.

CNC Milling Applications – What is CNC Milling Used for

Because the milling allows a very high precision without altering the structure of the material with a good rate of manufacture, CNC Milling is becoming increasingly common as its machine range, control systems and cutting tools are just growing. Our CNC Milling service is used to produce a variety of custom-designed CNC milling parts and products in all areas of the industry: Electronics industry, Marine industry, Millitary industry, Aerospace industry, Medical industry, Automotive industry, Agricultural industry, Machine tool industry, High-tech industry, Semiconductor industry, Food industry, etc.

Product detail pictures:

Related Product Guide:

We always get the job done to be a tangible staff to ensure that we can easily offer you the best high-quality and the greatest value for Wholesale China Cnc Milling Parts Factory Quotes – Factory black oxidation aluminum milling precision parts – Senze , The product will supply to all over the world, such as: Switzerland, Bangladesh, Costa rica, Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires please do not hesitate to contact us. Thank you - Your support continuously inspires us.

CNC Machining Parts

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!