Wholesale China Custom Turned Machining Parts Factory Quotes – Cutomized Turning Rod Machining Lathe Parts – Senze

Wholesale China Custom Turned Machining Parts Factory Quotes – Cutomized Turning Rod Machining Lathe Parts – Senze Detail:

What is Turning machining?

CNC turning is a particular form of the precision CNC machining process that holds a cylindrical workpiece in a chuck and rotated, while the cutting tool is fed to the piece and removing material to get the desired CNC turned components, leaving an excellent surface finish that sometimes requires no post-processing. Turning can be performed on the outside or inside of the workpiece to produce tubular components to diverse geometries.

When it comes to the CNC turning process, the subtractive manufacturing method is typically performed on CNC lathe or turning center. Before the cutting, G-code and turning machine need to be prepared, then secure the blank bar of stock material in the chuck of spindle, the chuck holds the piece in place when the spindle rotates. With the spindle spins to certain speed, a stationary single-point CNC turning cutter will move on a linear path that parallel to the axis of rotation and remove excess material, reduce the diameter of the block, specify the dimension and create smooth finish, to get final custom CNC turned parts with desired specification.

Feature for Turning machining

1. Machining round parts.

2. Mainly uses a turning tool to turn a rotating workpiece.

3. Used for drills, reamers, reamers, taps, dies and knurling tools.

4. High speed, high precision

CNC machining includes turning and milling technical.

Surface finish for cnc turning machining

Polishing, Anodized, Anodizing, Bead sand blasting, Chrome plated, Powder coated, PVD coating, Etching, Titanium coated, Vacuum coating, Nickel plating, Zinc plated, Chrome plated, Oxide black, and so on.

Working process for cnc machining

Package and shipping for CNC machining parts

1.Shock bubble film and foam 2.Suitable carton size 3.Suitable logistics

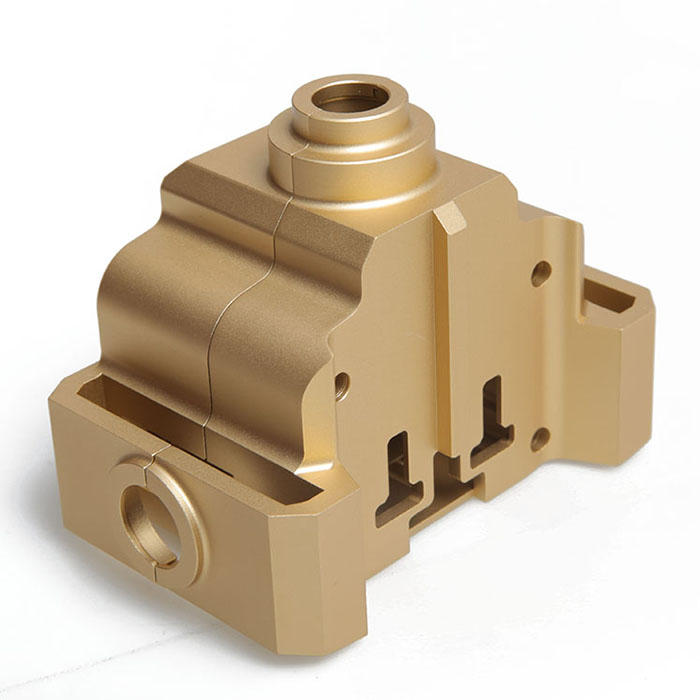

More parts photos for cnc machining parts

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand overseas business" is our development strategy for Wholesale China Custom Turned Machining Parts Factory Quotes – Cutomized Turning Rod Machining Lathe Parts – Senze , The product will supply to all over the world, such as: Marseille, Porto, Buenos Aires, We can give our clients absolute advantages in product quality and cost control, and we have full range of molds from up to one hundred of factories. As product updating fast, we succeed in developing many high quality products for our clients and get high reputation.

CNC Machining Parts

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.