Products

-

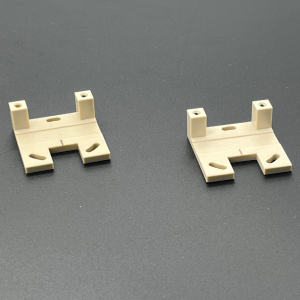

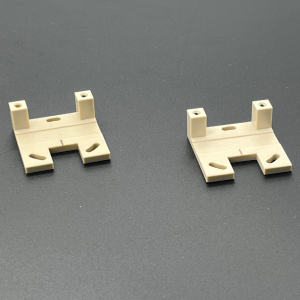

Custom Prototyping Product Medical Device PC ABS Nylon Peek Cnc Machining Plastic Part

CNC Milling Machining Parts.

Material: PEEK, PC,ABS, Plastic

Surface Finish: Polishing, remove the burrs and sharp edge.

We specialize in custom CNC Milling Parts, CNC Turning Parts, 5 Axis CNC Machining Parts, Mold Parts, Sheet Metal Fabrication,Die Casting,3D printing service etc,the quality of our products is very good,if you have any inquiry,please contact with me.

-

High Precision CNC Medical Device Part CNC Machining Service

CNC Milling Machining Parts.

Material: Stainless Steel

Surface Finish: Polishing, remove the burrs and sharp edge.

We specialize in custom CNC Milling Parts, CNC Turning Parts, 5 Axis CNC Machining Parts, Mold Parts, Sheet Metal Fabrication,Die Casting,3D printing service etc,the quality of our products is very good,if you have any inquiry,please contact with me.

-

OEM PrecisionTurning Milling Al6061 Metal 5 Axis CNC Machining Service Aviation Parts

CNC Milling Machining Parts.

Material: Aluminum

Surface Finish: Polishing, Anodized, remove the burrs and sharp edge.

We specialize in custom CNC Milling Parts, CNC Turning Parts, 5 Axis CNC Machining Parts, Mold Parts, Sheet Metal Fabrication,Die Casting,3D printing service etc,the quality of our products is very good,if you have any inquiry,please contact with me.

-

China Manufacturer Custom Anodized Black Blue Aluminum Cnc Machining Parts

Black and Blue CNC Machining Parts.

Aluminum material,anodized black or blue color.

We professionals in precision CNC machining and 3D printing for over 10 years, covering automotive, medical, aerospace, and defense industries, semiconductor parts, etc.

Our advantage are MOQ 1 piece, competitive price, and fast delivery time.

Any interesting, please contact us freely.

-

Custom Aluminum CNC Machining Parts Precision Metal CNC Milling Electronical Parts

CNC Milling Machining Parts.

Material: Aluminum

Surface Finish: Polishing, Anodized, remove the burrs and sharp edge.

We specialize in custom CNC Milling Parts, CNC Turning Parts, 5 Axis CNC Machining Parts, Mold Parts, Sheet Metal Fabrication,Die Casting,3D printing service etc,the quality of our products is very good,if you have any inquiry,please contact with me.

-

High Quality Cnc Milling Turning Lathe Machining Parts For Automotive Spare Parts Service

Custom High Precision CNC Machining Parts.

Our manufacturing capabilites are below:

1.3/4/5-Axis CNC Milling/Precision Turning

2.Vacuum Casting/Silicone/Rubber parts.

3.3D printing/SLA/SLS

4.Sheet Metal Fabrication

5.Injection Molding

6.Surface FinishingWelcome to contact us any time if you need.

-

Factory Oem Customized Precision Oem Anodizing Aluminum Brass Copper Titanium Alloy Cnc Milling Parts For Aviation Parts

-

CNC turning milling machining Service

- Material:

-

Aluminum, Steel, Iron, Stainless Steel, Plastic

- Surface treatment:

-

OEM made

- Tolerance:

-

±0.01mm

- Drawing needed:

-

2D 3D format

- Application:

-

Electronics/Industrial/MachinaryIf you want to know more information, welcome to contact us!

-

-

Turing Mass Production Cnc Engine Spare Parts Presicion Cnc Machining Service

-

CNC turning milling machining Service

- Material:

-

Aluminum, Steel, Iron, Stainless Steel, Plastic

- Surface treatment:

-

OEM made

- Tolerance:

-

±0.01mm

- Drawing needed:

-

2D 3D format

- Application:

-

Electronics/Industrial/MachinaryWe are professional hardware plastic prototype model manufacturing, CNC lathe processing, 3D printing,Surface Treatment, SLA and SLS.Welcome to contact us!

-

-

Custom Plastic Cnc Machining Service Cnc Precision Part

Custom Precision CNC Machining Parts.

Material: Aluminum Clear Acrylic,Resin,Stainless Steel

Surface Finish: Smooth,Polishing,Anodized Silver color.

We are professional hardware plastic prototype model manufacturing, CNC lathe processing, 3D printing,Surface Treatment, SLA and SLS. If you have any requirement, welcome to contact me.

-

OEM Custom Stainless Steel Aluminium Alloy high Precision Automatic Machine CNC Machining Services Metal Parts

Product Material1) AL1060, AL6061, AL6061, AL5052 etc.

2) Steel, mild steel, SS201, SS303, SS304, SS316, SS316L etc.

3) Brass, Copper

4) ABS, PP, PE, PC, POMSurface TreatmentAnodized, powder coating, lacquer coating, black oxide, printing, matte, glossy, texturedSizeAccording to customers’ drawingsDrawing FormatSTEP,STP, DWG, IGS,IGES,PDFOur Advantage1)Full Service,From all your prototypes,rapid tooling and low-volume manufacturing to finishing/assembly,2)Competitive Price,Our price will be 50%-60% cost lower compared to western prices. we supply parts short lead- time, excellent quality and low cost.

3)Quality Guarantee,100% QC inspection before delivery, we can provide inspection form.CertificatesISO 9001:2015 & IATF 16949Payment TermT/T, L/C, Trade Assurance -

High Quality Factory OEM Customized AL6061 AL6063 AL7075 CNC Machining Industrial Parts

Black and nature color anodized CNC Machining Parts.

Aluminum material,anodized surface treatment.

We professionals in precision CNC machining and 3D printing for over 10 years, covering automotive, medical, aerospace, and defense industries, semiconductor parts, etc.

Our advantage are MOQ 1 piece, competitive price, and fast delivery time.

Any interesting, please contact us freely.

-

High Quality OEM Custom CNC Manufacturer Prototype Service Rapid Prototyping Micro Cnc Machining Parts

Product Material1) AL1060, AL6061, AL6061, AL5052 etc.

2) Steel, mild steel, SS201, SS303, SS304, SS316, SS316L etc.

3) Brass, Copper

4) ABS, PP, PE, PC, POMSurface TreatmentAnodized, powder coating, lacquer coating, black oxide, printing, matte, glossy, texturedSizeAccording to customers’ drawingsDrawing FormatSTEP,STP, DWG, IGS,IGES,PDFOur Advantage1)Full Service,From all your prototypes,rapid tooling and low-volume manufacturing to finishing/assembly,2)Competitive Price,Our price will be 50%-60% cost lower compared to western prices. we supply parts short lead- time, excellent quality and low cost.

3)Quality Guarantee,100% QC inspection before delivery, we can provide inspection form.CertificatesISO 9001:2015 & IATF 16949Payment TermT/T, L/C, Trade Assurance -

Custom Artwork statue of liberty Print SLA SLS 3D Printing rapid prototype FDM PLA 3D Printing service

Product Material1) Resin,transparent resin,high toughness resin,yellow resin,grey resin, etc.

2) Nylon, Black Nylon PA12, white nylon,etc.

3) Red candle,flexible glue,etc.

4) Metal: Aluminium Alloy,316 Stainless Steel,etc.Surface TreatmentAnodized, powder coating, lacquer coating, black oxide, printing, matte, glossy, texturedSizeAccording to customers’ drawingsDrawing FormatSTEP,STP, IGS,IGES,PDFOur Advantage1)MOQ: One pcs is OK.2)Lead time: The sample lead time is shortly.

3)Full Service:From all your prototypes,rapid tooling and low-volume manufacturing to finishing/assembly,.4)Competitive Price:Our price will be 50%-60% cost lower compared to western prices.

3)Quality Guarantee:100% QC inspection before delivery, we can provide inspection form.CertificatesISO 9001:2015 & IATF 16949Payment TermT/T, L/C, Trade Assurance -

Customized precision CNC milling service machining metal block machined anodized aluminum parts

Materials for cnc machining Surface finish for cnc machining Polishing, Anodized, Anodizing, Bead sand blasting, Chrome plated, Powder coated, PVD coating, Etching, Titanium coated, Vacuum coating, Nickel plating, Zinc plated, Chrome plated, Oxide black, and so on. Other more product what is cnc machining? CNC can be used to produce machining parts and prototypes very quickly with high precision, at a high production rate, the materials used are strong and durable for test... -

Low Price High Quality OEM Custom CNC Manufacturer Prototype Service Rapid Prototyping Micro Cnc Machining Parts

Materials for cnc machining Surface finish for cnc machining Polishing, Anodized, Anodizing, Bead sand blasting, Chrome plated, Powder coated, PVD coating, Etching, Titanium coated, Vacuum coating, Nickel plating, Zinc plated, Chrome plated, Oxide black, and so on. Other more product what is cnc machining? CNC can be used to produce machining parts and prototypes very quickly with high precision, at a high production rate, the materials used are strong and durable for testing. CNC machini...